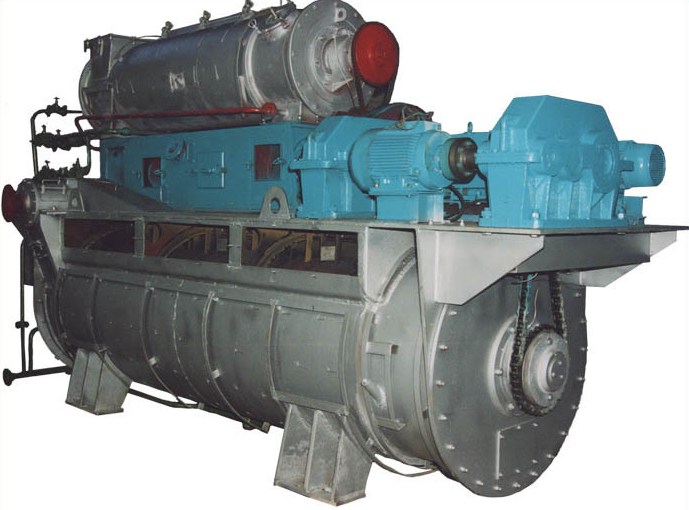

The unit is intended for production of fishmeal and cod-liver oil from fish waste and less valuable breeds of fish installed in coastal fish processing factories as well on board fishing boats.

Technical characteristics:

1. Productive capacity (of raw material), t/day - 30-35

2. Operation - continuous

3. Raw material size - pieces with mass not more than - 10 kg.

4. Meal output, % from raw material mass - 18…22

5. Steam working pressure, kg/cm2 - 5

6. Steam consumption without evaporating system, kg/hr, max - 680

7. The amount of water at 50C

needed for meal cooling, kg/hr, max - 700

8. Water pressure, kg/cm2 - 6

9. Fresh water consumption for separator, m3/hr, max - 0,05

10. Installed motor power, kWt, max - 75

11. Final product obtained fodder meal State Standard - 2116-82

cod-liver oil State Standard - 1304-76

12. Dimensions, mm, max

-length - 7635

-width - 5900

-height - 4050

13. Mass, kg, max – 18215

The operation of A1-IZHR unit:

The fish or other product to be processed is dumped into a chopper, if the fish is quite small it can be dumped directly in the bunker reservoir. The mash, which may include wash water, passes into a bunker reservoir. An elevating screw lifts the mash into a cooking tank while excess water is drawn off. The cooker is heated by steam at a temperature from 50 to 100 C degrees. From the cooking tank the mash moves to a cylinder with a press which removes water in the form of liquor and leaves the mash with moisture content of 45-50%%. The liquor is sent by pump to the residue separator where solids are separated then mixed with mash by the screw mixer and after that dried in the drier vessel. The mass comes out with moisture content of 10-12%. A fan exhausts the moisture with waste steam into the atmosphere through another separator, which returns any particulate matter to the mash line.

At this stage a magnetic device removes any metallic debris before the mass is moved by pneumatic transport into a milling machine. From this the dried meal passes though two cyclone separators, which ultimately deposits the meal in a discharge nozzle, exhausting the air through a fan.

Meanwhile the raw liquor, heated by steam at temperature of 85-95 C degrees is passed though an oil separator. Pump returns final product oil to a heated storage tank with product outlet, and the liquor is further processed though evaporating stages and to recover more oil which is returned by pump to the system while excess air and water are evacuated.

In order to install the fishmeal and oil unit A1-IzhR at the coastal factories it is necessary to have:

1. The source of water supply and purification works or sewage system.

2. Boiler room or steam generator with steam output parameters up to 1 t, 5 atmospheres.

3. Electro – energy source with 380 V 50 Hertz, voltage not less than 100 kWt.

4. Starting-protective electric equipment.

The unit is operated by one person as all control functions are combined in one control panel.

1. Productive capacity (of raw material), t/day - 30-35

2. Operation - continuous

3. Raw material size - pieces with mass not more than - 10 kg.

4. Meal output, % from raw material mass - 18…22

5. Steam working pressure, kg/cm2 - 5

6. Steam consumption without evaporating system, kg/hr, max - 680

7. The amount of water at 50C

needed for meal cooling, kg/hr, max - 700

8. Water pressure, kg/cm2 - 6

9. Fresh water consumption for separator, m3/hr, max - 0,05

10. Installed motor power, kWt, max - 75

11. Final product obtained fodder meal State Standard - 2116-82

cod-liver oil State Standard - 1304-76

12. Dimensions, mm, max

-length - 7635

-width - 5900

-height - 4050

13. Mass, kg, max – 18215

The operation of A1-IZHR unit:

The fish or other product to be processed is dumped into a chopper, if the fish is quite small it can be dumped directly in the bunker reservoir. The mash, which may include wash water, passes into a bunker reservoir. An elevating screw lifts the mash into a cooking tank while excess water is drawn off. The cooker is heated by steam at a temperature from 50 to 100 C degrees. From the cooking tank the mash moves to a cylinder with a press which removes water in the form of liquor and leaves the mash with moisture content of 45-50%%. The liquor is sent by pump to the residue separator where solids are separated then mixed with mash by the screw mixer and after that dried in the drier vessel. The mass comes out with moisture content of 10-12%. A fan exhausts the moisture with waste steam into the atmosphere through another separator, which returns any particulate matter to the mash line.

At this stage a magnetic device removes any metallic debris before the mass is moved by pneumatic transport into a milling machine. From this the dried meal passes though two cyclone separators, which ultimately deposits the meal in a discharge nozzle, exhausting the air through a fan.

Meanwhile the raw liquor, heated by steam at temperature of 85-95 C degrees is passed though an oil separator. Pump returns final product oil to a heated storage tank with product outlet, and the liquor is further processed though evaporating stages and to recover more oil which is returned by pump to the system while excess air and water are evacuated.

In order to install the fishmeal and oil unit A1-IzhR at the coastal factories it is necessary to have:

1. The source of water supply and purification works or sewage system.

2. Boiler room or steam generator with steam output parameters up to 1 t, 5 atmospheres.

3. Electro – energy source with 380 V 50 Hertz, voltage not less than 100 kWt.

4. Starting-protective electric equipment.

The unit is operated by one person as all control functions are combined in one control panel.